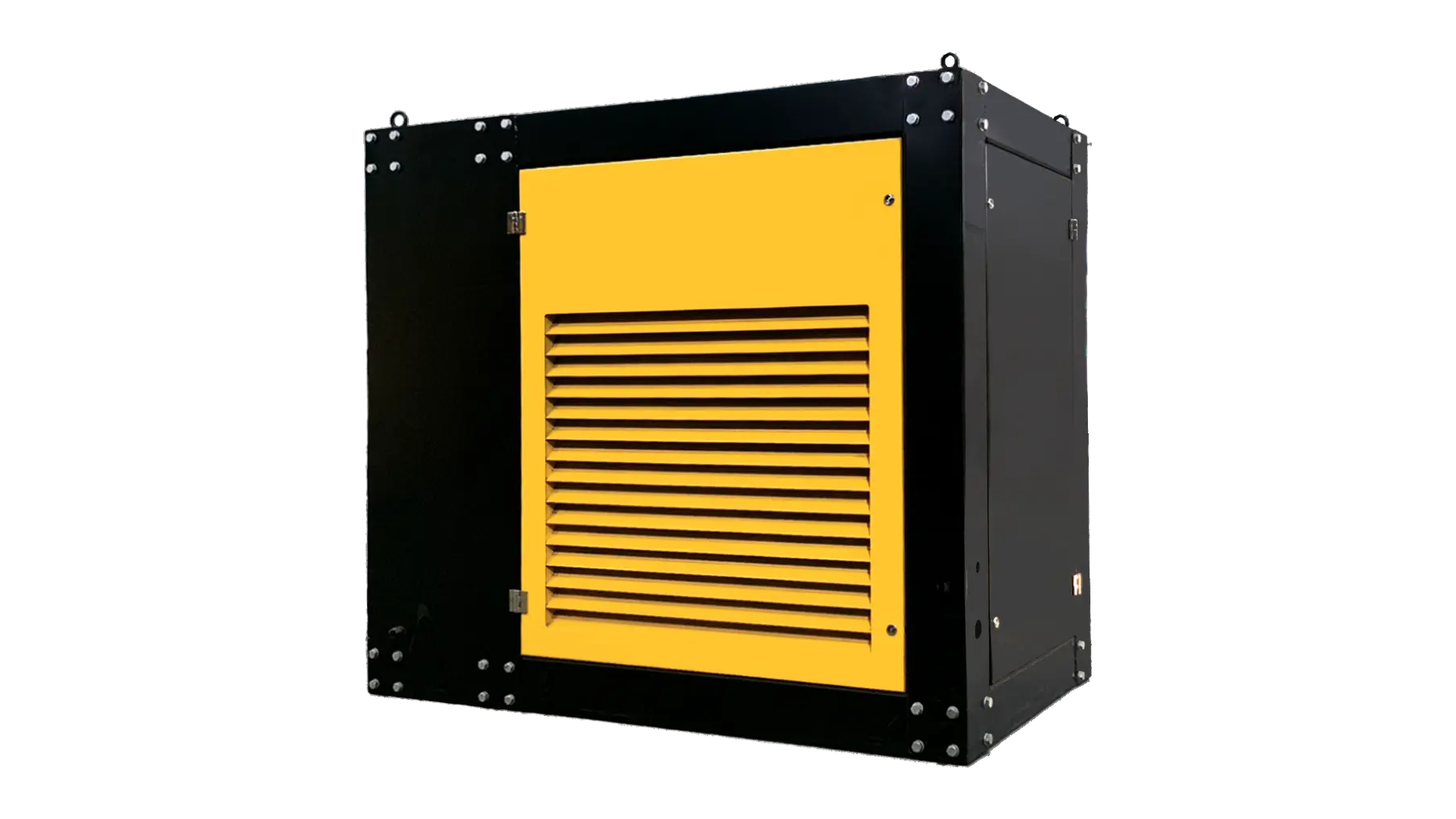

B Range- Electric Driven Air/Nytrogen Booster

Electric Driven Oil-Free Booster Compressor

The unit's performance complies with ISO1217 Ed.3 Annex C standards, adopting booster technology (B). The core booster compressor is sourced from Atlas Copco, GE, or EastX, and is integrated with a containerized frame design for convenient transportation and flexible deployment.

| Model | B40 | B70 | B120 |

|---|---|---|---|

| General | |||

| Dimensions (L × W × H, mm) | 2,650×1,600×2,700 | 2,650×1,600×2,700 | 4,600×2,200×2,700 |

| Mass* (kg) | 2,900 | 1,150 | 8,250 |

| Air Outlet (in) | G2 | G2 | G2 |

| Installed Motor | |||

| Nominal Power (kW) | 132 / 220 | 15 | 132 |

| Power Supply (V / Ph / Hz) | 380 / 3 / 50 | 380 / 3 / 50 | 380 / 3 / 50 |

| Performance | |||

| Compressible Gas | Dry Air | Dry Air / Nitrogen | Dry Air / Nitrogen |

| Max. Capacity FAD (m³/min) | 20 / 40 | 1.8 | 15 |

| Inlet Pressure (bar(e)) | 6–10 | 6–10 | 6–10 |

| Max. Outlet Pressure (bar(e)) | 42 | 70 | 120 |

1. Unit perfomance measured according to ISO1217,Ed3,Annex C

2. "B" means booster. Booster main head is Atlas Copco、GE or EastX brand.

3. *Container frame inclusive

Features

- Performance strictly follows ISO1217 standards, ensuring the authority of testing and data reliability.

- The booster main unit is compatible with Atlas Copco/GE/EastX, meeting industrial-grade high-pressure boosting requirements.

- 100% oil-free design ensures gas purity, suitable for precision manufacturing and sensitive scenarios.

- Rainproof frame design supports rapid deployment and outdoor all-weather operation.

Advantages

- Maximum capacity up to 40m³/min (B40), high-pressure output meets stringent industrial demands.

- Compact container frame facilitates transportation and site adaptation.

- 380V/3-phase power drive, power range from 15-220kW, stable adaptation to different working conditions.

- Supports dry air and nitrogen boosting, widely used in industries such as energy, chemicals, and electronics.