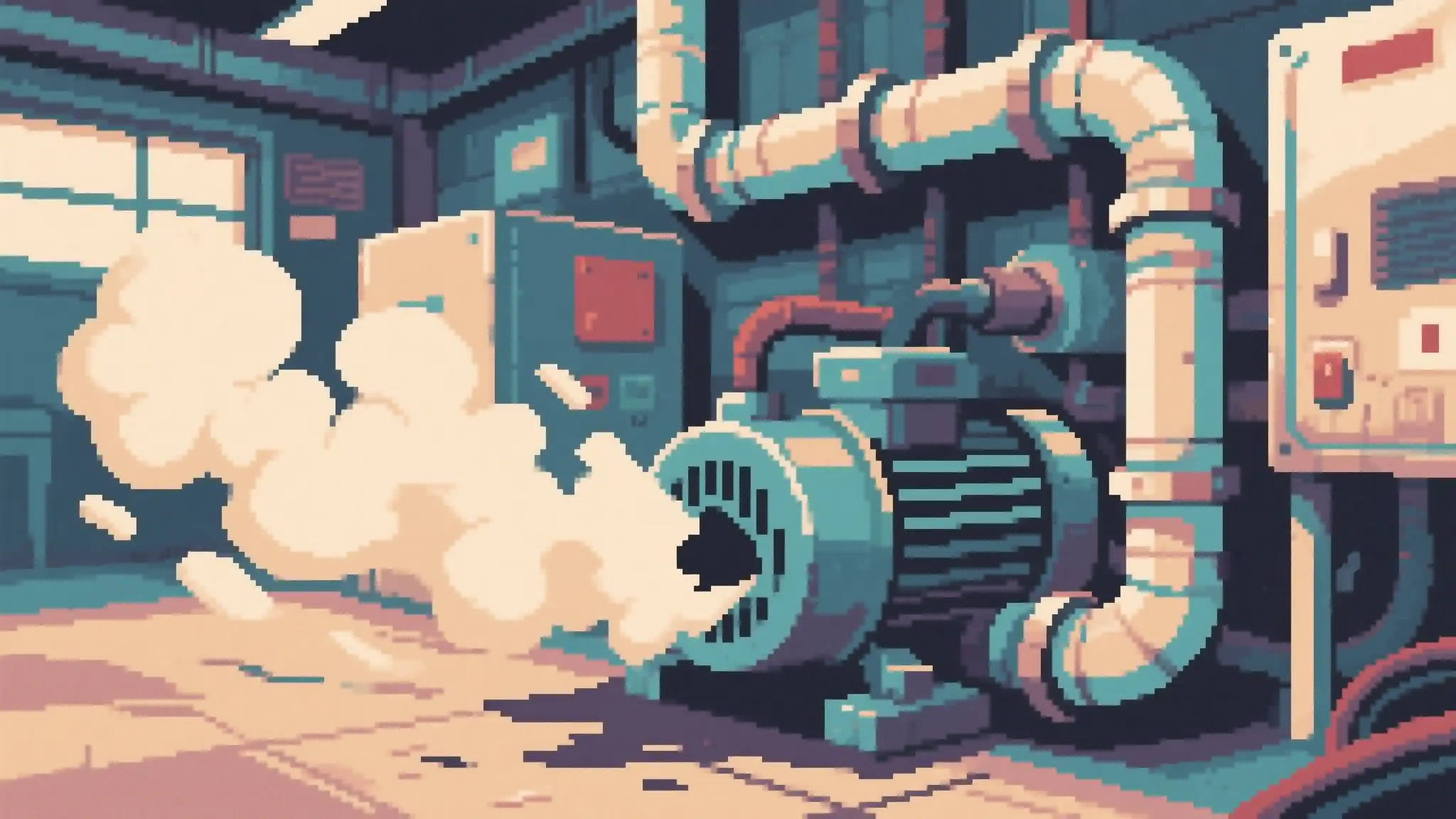

Excessive vibration in air compressors is a common issue that, if not addressed in time, can affect equipment performance and lead to a range of economic losses and safety hazards for businesses. This article analyzes the causes of excessive vibration in air compressors, its impact on businesses, and provides professional solutions to help companies address this challenge effectively.

1. Common Causes of Excessive Vibration in Air Compressors

▍Unstable Foundation

An improperly designed or poorly constructed foundation may cause the equipment to resonate during operation, leading to excessive vibration. Common signs of an unstable foundation include loose anchor bolts and cracked foundation concrete.

▍Rotor Imbalance

The rotor is a key component in an air compressor. Its balance directly affects the operational state of the equipment. Rotor imbalance can be caused by manufacturing defects, prolonged wear, or foreign objects entering the system. When the rotor’s mass is unevenly distributed, centrifugal forces during high-speed rotation cause severe vibrations.

▍Bearing Damage

Bearings are crucial components supporting rotor rotation. Bearing damage may result from inadequate lubrication, overloading, or wear and aging. When bearings suffer from wear, cracks, or excessive gaps, rotor instability occurs, leading to vibration.

2. The Losses Caused by Excessive Vibration in Air Compressors

Excessive vibration in air compressors is not only a technical issue but also an economic one. Below are the direct and indirect losses businesses may face:

▍Equipment Damage and Increased Maintenance Costs

Excessive vibration accelerates wear on key parts such as bearings, rotors, and gears. Prolonged operation may cause severe damage to the equipment, requiring expensive repairs or even complete replacements.

▍Decreased Production Efficiency

Vibration can affect the air compressor’s air output stability and energy efficiency, leading to reduced production efficiency. Furthermore, equipment malfunctions may halt the production line, delaying production schedules, resulting in order delays and customer dissatisfaction.

▍Increased Energy Consumption

Studies show that vibration issues can increase the energy consumption of air compressors by 10%-20%. Over time, this significantly raises electricity costs for businesses.

Data Support:

- A study by the U.S. Department of Energy (DOE) found that vibration problems in air compressor systems could reduce energy efficiency by 10%-15%.

- A report from the European Compressors Air Association (PNEUROP) indicates that vibration-induced mechanical losses and air leaks can increase energy consumption by 10%-20%.

▍Safety Hazards and Personnel Risks

Severe vibration can cause parts to loosen or even fall off, leading to safety accidents.

▍Damaged Brand Reputation

If equipment failure leads to decreased product quality or delivery delays, the company’s market reputation could suffer, affecting customer relationships and long-term partnerships.

3. Solutions for Air Compressor Vibration Problems

To address the causes and losses mentioned above, we recommend the following measures:

- Regularly inspect the foundation to ensure stability.

- Perform dynamic balancing corrections to ensure rotor balance.

- Enhance bearing maintenance to ensure optimal bearing performance.

- Choose FOOENS oil-free air compressor rentals to solve vibration issues thoroughly.

Choosing FOOENS oil-free air compressor rentals helps you reduce equipment procurement costs while offering flexible usage plans and comprehensive technical support. FOOENS specializes in oil-free air compressor rental services with an on-site engineering team to ensure optimal operation.

With FOOENS rental solutions, you can resolve vibration issues and boost production efficiency with the highest quality service.